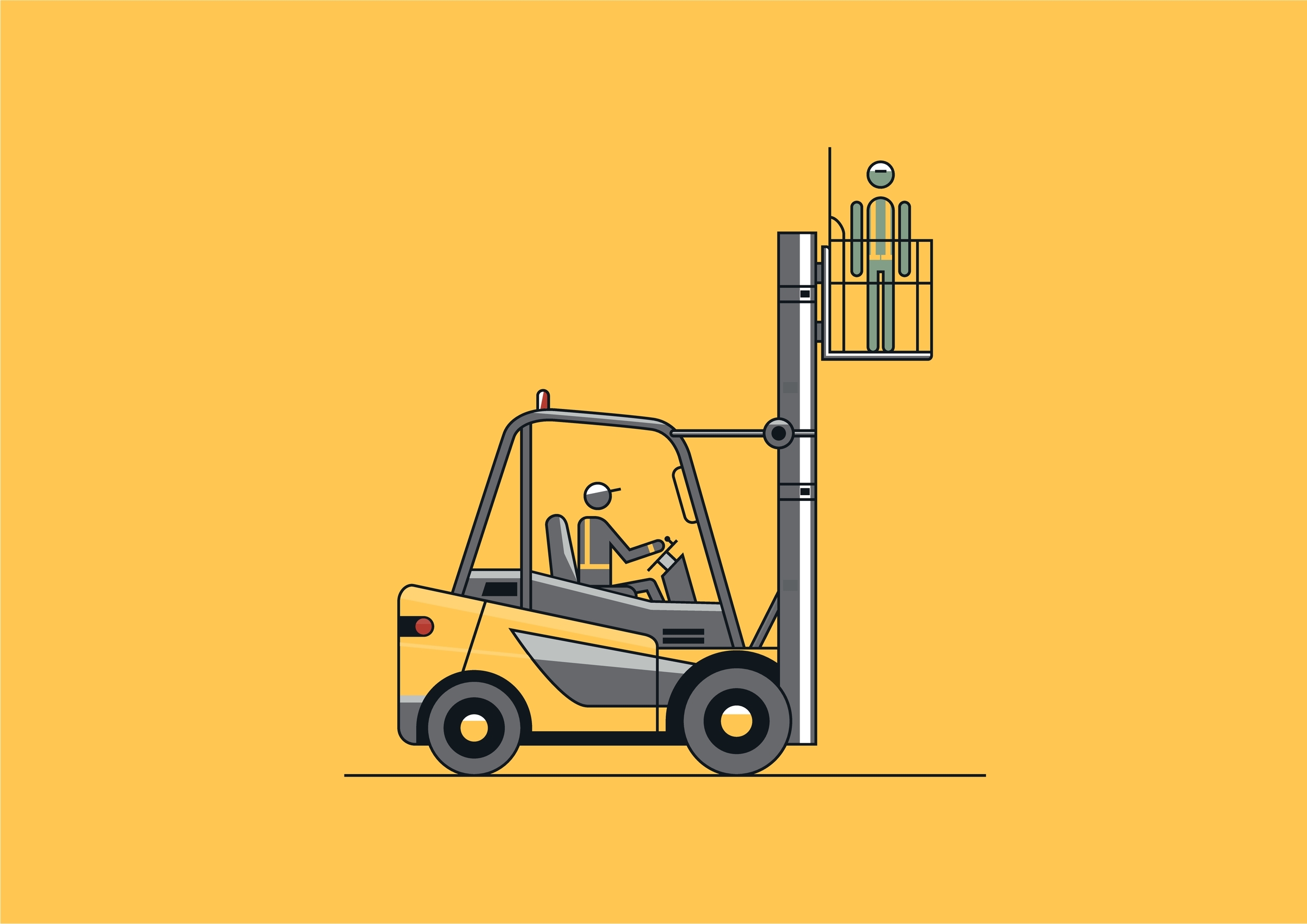

Forklift safety cages are platforms used to lift a warehouse employee or employees to high-access areas to perform an occasional or short-duration task. They can also be referred to as a ‘man cage’, a ‘man basket’ or a ‘forklift working platform’. Safety cages provide a safe and mobile working space for workers to perform a variety of different tasks within a warehouse.

Forklifts are generally used for lifting materials and products, but when a safety cage is added, they can also be used to lift people. These are incredibly useful in situations where access to high places is needed.

Working at height poses a risk to health and safety, which is why forklift safety cages are an ideal choice to have on-site, or in the workplace in case of any event where working from a height is required. Forklift cages can transform a forklift into a stable and secure platform.

When should you use a Forklift Safety Cage?

Forklift and reach trucks have been designed to primarily lift materials and heavy objects – not people. However, there became an evident need for a safe way to secure means of access when a task needs to be carried out at height. A forklift safety cage can be used in these circumstances to provide a safe means of access such as improvised stairs, to be used as a platform itself, or as an improvised ladder.

- They can be used to carry out emergency repair work e.g tasks that, if not carried out, would immediately pose a risk to employee safety.

- Non-routine maintenance tasks

- When a forklift platform provides a safer means of access than scaffolding, portable ladders etc.

- When it is not possible to hire dedicated people lifting equipment due to the short duration or temporary nature of a job.

Steps to using a Forklift Safety Cage, safely.

Training

The most important thing about using a forklift safety cage is ensuring that all those involved in the use of the equipment are adequately trained on how to use it, including knowing what to do if there is an emergency.

Safety checks should be carried out by a trained individual, along with the equipment being regularly inspected and maintained to be sure it is in full working order.

Communication

There needs to be clear communication between the operator of the forklift and the worker that will be in the cage.

Be Aware Of The Load limit

It is important to check the load limit before attaching a safety cage to your forklift. The load capacity will vary based on the manufacturer and model of the forklift. Always be sure to include the weight of the safety cage, along with the weight of the people and tools that will be inside the safety cage.

Safely Securing the Platform

It is imperative that the platform is attached securely to the forklift carriage or backrest. In some cases, the platform is attached to both the carriage and the backrest. This is necessary to ensure that the forklift is able to support the total weight of the safety cage, and its content.

Wear the correct protective equipment

When using a forklift and forklift safety cage, equipment should be supplied such as hard hats, gloves, steel toe-capped boots, high-visibility clothing, and a harness or lanyard.

Providing more stability and convenience than other methods of working at height, a safety cage is an essential piece of equipment to accompany a forklift or lift ruck. For more information about forklift safety, read our other useful guides here , or contact us for any other information you may need.